|

|

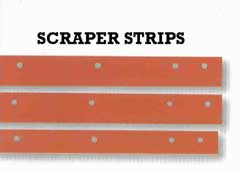

- Better sealing from end

to end of the mold cavity.

- Wear resistance is increased

and improved.

- Made from tougher, wear

resistant material

- Lasts longer, reduces maintenance,

cuts costs.

- With or without mounting

holes.

- Scraper strips are perfect

for the Mk-3, Mk-5, and 230X.

|

| |

|

|

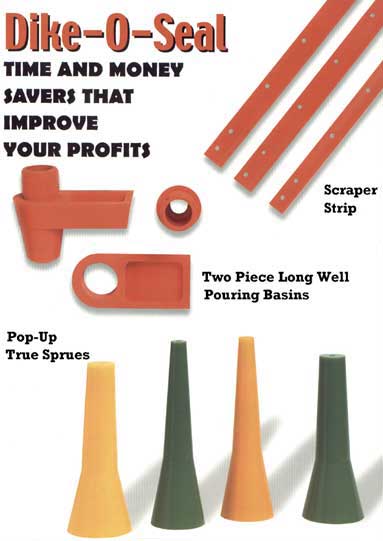

- Dike-O-Seal's pouring basin

is standardized.

- Our pouring basin is moveable

- Located anywhere for pouring

ease.

- Greater flexibility when

pouring in different positions.

- Improves productivity and

lower costs.

- Requires no ladle spout

changing

- Saves time and money, improving

bottom line.

- Two piece or individual

pouring cup.

- Available with 2"-8

or M48 thread.

|

| |

|

|

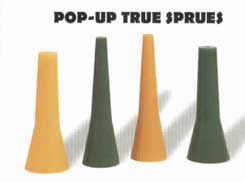

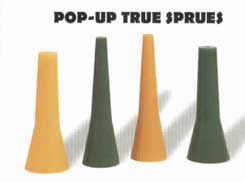

- Eliminates the need to

drill a pouring basin, eliminating loose sand.

- Reduces scrap due to loose

sand.

- Improves accuracy and eliminates

drill wear.

- Quality of the casting

is vastly improved.

- No loose sand to fall into

the mold cavity.

- Saves time and money and

improves casting quality.

|

| |

|

These Dike-O-Seal products are manufactured from long

lasting Abra-Shun®, a polyurethane recipe specified by engineers at

Dike-O-Seal that's tougher than iron. |

|